RF Press Systems

RfsProtech’s Radio Frequency Presses are used in a variety of industries including kitchen cabinets, door frames, panels, laminated beams, along with many other applications. Radio Frequency curing is the fastest method for curing wood components; parts can be cured in a matter of minutes and then be further processed (ie. sanded or machined). Using older methods, such as clamping wood parts and waiting for the ambient heat (room temperature) to dry the glue lines are very slow.

ABOUT

The SL Slant Gluer is an economical, high quality edge gluer with the platen mounted on a 45° angle for easy loading and placement of stock within the press. The SL model is compact and requires minimal floor space, but because of the radio frequency technology, it has the capability for high production while providing consistent glue joint strength.

The press features pneumatic pressure on the edge of the panel to close the joints and a 6 kW Radio Frequency Generator for rapid curing of the glue joints. The SL Series comes in 2 standard models, a 36" X 48" and a 36" x 60". Optional sizes from 48" wide to 120" long can be manufactured.

The ergonomics of the press, the control over stock placement, and the affordable price are all features that have made the SL Slant Gluer a favorite workhorse in the smallest of shops to the largest of woodworking companies.

ABOUT

The RfsProtech "EG" model Edge Gluer is a high production workhorse for all your edge/face gluing needs.

Its pusher feed system is a great solution for gluing panels, door parts, window parts, furniture parts, flooring, laminated beams and a vast variety of other products. Generators are available from 10kW to 200 kW and can come with or without in-feed and out-feed material handling systems.

ADVANTAGES

- Heavy duty frame construction prevents distortion, providing high quality production and long life.

- Advanced solid-state generator design and all aluminum cabinet construction for efficiency and high production rates.

- Adjustable height side pressure cylinders for proper positioning on varying stock thicknesses.

- Premium hydraulic equipment includes all necessary valves, plumbing and controls.

- Intelligent controls, utilizing a PLC featuring operator safeties, manual and automatic production modes, and a full range of optional production aids.

- Powered in-feed table with inverter control for fast and precise loading of stock and dead roll out-feed standard equipment.

ABOUT

This is a heavy-duty edge gluer with a slat bed type construction for high production gluing applications. The slat bed design allows for material to be loaded during the curing cycle. Once the cure or cooking cycle is completed, the top platen is raised and the slat bed conveyor which extends through the machine and out to the load area feeds the next load into the press area and simultaneously discharges the cured load.

The machine features hydraulic side and top pressure. Generators sizes vary from 50 to 200 kW.

OPTIONAL

- Hydraulic vs. Air Pressure

- Radio Frequency Auto Tune

- Radio Frequency Auto Cure

- In-feed Conveyor

- Out-feed Conveyor

- Automatic Glue Extruder

- Material Handling

- Custom press sizes, wider longer

SPECIFICATIONS

- Curing capacity is (52") 1320mm wide x (240") 6100mm x (6") 152 mm thick. Other optional sizes available

- The press frame will be computer designed to minimize deflection under load and for long machine life.

- The slat conveyor passes through the press and will include the lay-up area of the gluer. The in-feed area is an extension of the slat conveyor.

- Top pressure is applied by hydraulic cylinders to insure precise panel flatness of the panels.

- Removable top platen electrode – slides out of the press for easy glue cleaning.

- Edge pressure is applied by hydraulic cylinders.

- Generators bigger than 150 kW are water cooled.

- Automatic curing feature that utilizes the PLC in the press to determine when the glue lines are cured completely and then stops the press regardless of the timer setting.

ABOUT

A high quality 4-way clamp with its 38" by 78" clamping area mounted on a 45° angle for easy loading, positioning and removal of stock. The press features pneumatic pressure for the 4-way clamping of doors and panels. An internally mounted Radio Frequency Generator cures the glue joints in seconds. Complete with all controls and necessary safety devices.

SPECIFICATIONS

- The heavy welded steel frame is computer designed to minimize deflection under full working pressures.

- Clamping Area is 38" x 78" x 1 ¼” thick.

- Clamping pressure is applied by pneumatic cylinders to maximize pressure while requiring only plant line pressure (no booster compressors).

- Edge and end pressure applied by 1" bore x 2" stroke pneumatic cylinders.

- Each cylinder fitted with a shut-off valve for ease of use.

- Platen set at a 45° angle for easy access to the platen for placement, alignment and removal of stock.

- The internal solid state RfsProtech RF Generator can cure door/window joints in seconds.

- Controls are easy to understand, and feature a digital operator interface with messaging for operation and troubleshooting.

- Wired for 480 Volt 60 Cycle 3 Phase operation. Other voltages available, please specify.

ABOUT

RfsProtech designs in-feed and out-feed systems from small to high capacity projects. Our systems are designed by our own engineers who work together with the customer to come up with a solution matching the customers requirements. Our material handling systems can be fully automated and integrated with all of our machinery.

ABOUT

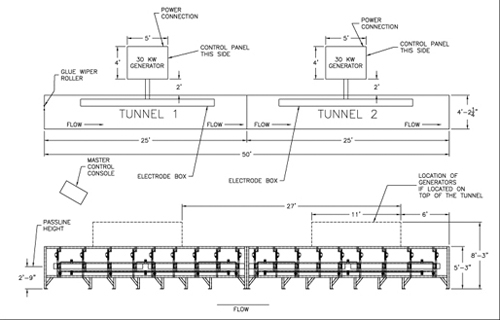

The Radio Frequency Press tunnel cures finger joints in a matter of seconds at speeds of 200ft/min plus. The RF Tunnel prevents finger-jointed boards from falling apart as they are bonded together as they feed through the tunnel. The RF tunnel saves on valuable floor space because it does not require a large buffer area for the joint to be cured at ambient heat.

ADVANTAGES

- Minimum Floor Space

- No Buffer Space Required

- Cures Joints In Seconds

- Cures Joints At High Speeds

- Eliminates Boards From Sticking Together

ABOUT

Our Radio Frequency Generators are designed for industrial applications in woodworking and other industries. The generators feature an enclosed cabinet, solid-state rectifiers, arc suppression and plate overload circuitry to maximize efficiency and performance.

Radio Frequency Generators come in a variety of kW sizes and are built according to the customer's application and production requirements.

ABOUT

A conveyorized glue spreader for application of adhesives. The device is a freestanding unit which can be placed in front of any press. Includes stainless steel in-feed rollers and out-feed flights for easy cleanup. The applicator roller is easily adjustable for accurate spreading of adhesive. A top pinch roller can be installed for glue coating thin parts such as veneers.

SPECIFICATIONS

- 20" working width

- Built as a freestanding system

- In-feed conveyor in various lengths with mild steel flights on 3" centers.

- Out-feed conveyor in various lengths with stainless steel flights on 3" centers.

ABOUT

This is a heavy-duty, radio frequency, plywood press utilizing hydraulic pressure for the precise pressing of plywood or other parts. The down-stroke platen is guided and easily accepts forms for curved parts. It is a very safe press to operate with a full sheet metal enclosure and numerous safety switches for interconnecting to a Radio Frequency generator.

The press is available in a variety of widths, thicknesses and heights.