Flooring Core Line

WHO NEEDS PLYWOOD?

WHEN YOU CAN MAKE YOUR OWN FLOORING BASE CORE

Cost effective.

Fast return on investment

Tested and proven product

Independence from plywood supplier

Minimum labor required for manufacturing

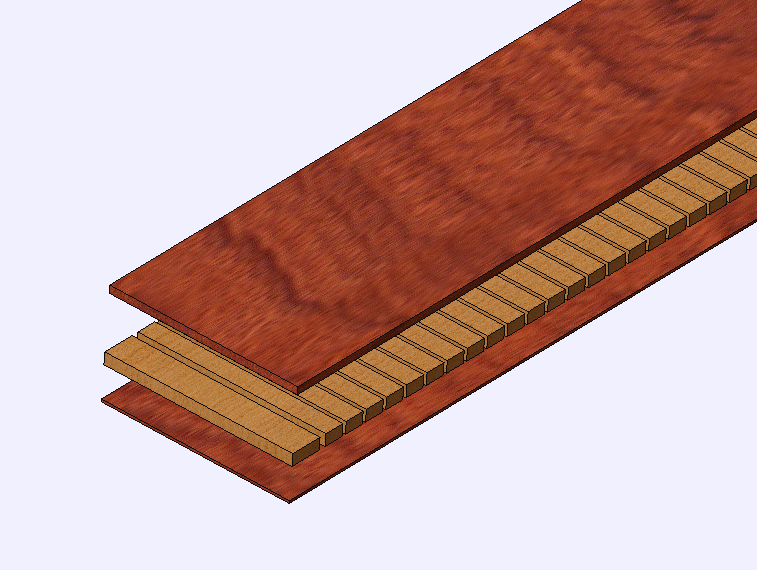

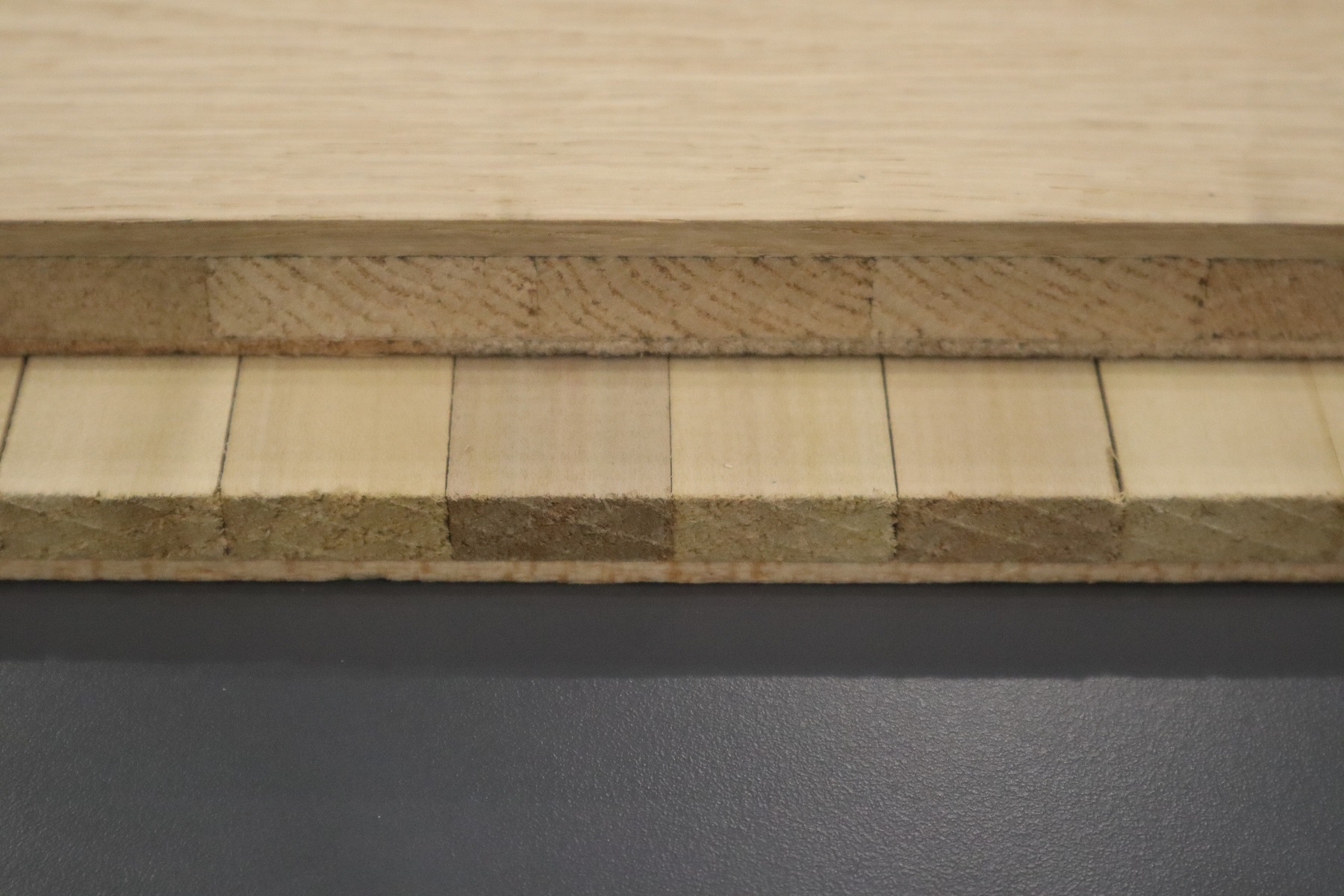

With the recent shortage and increased cost of plywood, Ogden Group has developed a manufacturing method that replaces plywood with a solid engineered core substrate. The solid core substrate consists of a 2-ply construction - a rotary peeled veneer bottom layer and a top layer comprised of sticks that are gang-ripped from 4/4 low-grade lumber. The wear layer would then be applied on top of the core substrate, just as it would be placed on plywood.

The substrate core is made into a panel that is 2’ wide by 8’ long. This panel is then ripped into the widths required for the flooring. Based on the 2’ x 8’ panel, the machinery system can produce approximately 30,000 sq. ft. of substrate core per shift.

There are several advantages of manufacturing your own solid engineered core.

- The cost of the solid engineered core is a fraction of the price of plywood

- You no longer need to rely on outside vendors to provide your substrate

- Significantly less glue lines on the solid core – resulting in increased tooling life

- Requires minimal labor due to the automation of the system

- A core that is 100% made in the USA

Call us for more information on how to produce your own core and become independent from overseas plywood manufacturing companies.